Working with radio controlled aircrafts, mobile HAM radios and other battery operated equipment I have long needed a precision instrument to measure true battery capacity and also to be able to discharge Lithium-Polymer batteries to a proper storage voltage. True battery capacity can only be measured by discharging the battery with a certain current and monitoring the voltage. The capacity might vary with current, so the discharge current must be close to the real operating current. The capacity can be less if higher currents are used. The Lithium-Polymer batteries have a recommended storage voltage, which is 3.8V per cell. This is approximately 50% of the capacity, where 4.2V is full and 3.0-3.2V is empty. If stored at a too high voltage there might be a reaction that causes gas to be generated and the battery swells. This is a dangerous condition as the battery might overheat and catch fire or even explode when charged or used. If stored at too low voltage the battery might discharge even more and experience another kind of chemical reaction that quickly deteriorates it's capacity or destroys it completely. The temperature and battery quality has an effect how quickly the battery deteriorates when stored. Good quality batteries can be stored at a high voltage for a much longer time before swelling. But even highest quality batteries are destroyed if the voltage drops too low.

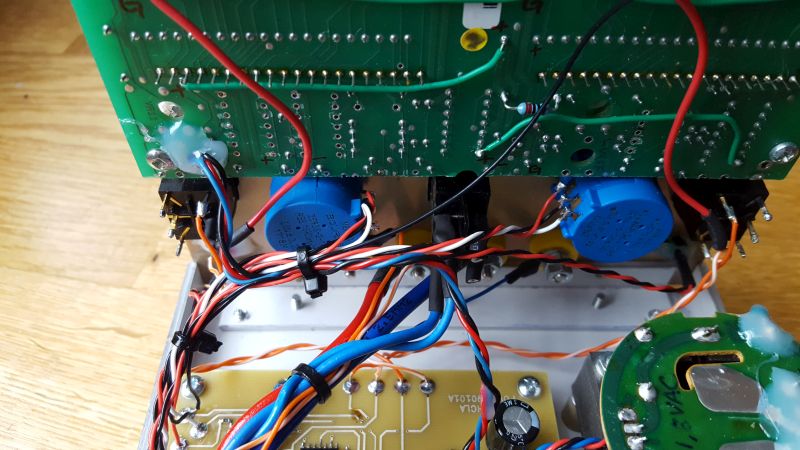

I degined the current sink to have an adjustable current sink capability between 0-10A, that can be set by a 10-turn precision potentiometer. A switch can be used to monitor either the actual current or the current setting on a LCD current display with 0.01A resolution. A cut-off voltage can be set with another 10-turn precision potentiometer between 0-10V. The current sink shuts down when the voltage drops below this setting. Another LCD display can be selected to show the cut-off voltage setting or the actual voltage with 0.01V resolution. There are separate voltage sensing connectors that can be used to sense the voltage without any voltage loss caused by wire resistance of the high current path. The cut-off condition is indicated by a LED and it can be restarted by toggling the ON/OFF swith to OFF and then ON again.

To measure battery capacity the battery voltage should be logged by a separate instrument while the current sink is discharging the battery. Set the current to a typical usage current. The cut-off voltage should be set to the minimum voltage and it will make sure the battery is not discharged too far. To discharge the battery to a storage voltage, set the cut-off voltage to the storage voltage. Have a modest discharge current as not to cause any unnecessary stress and wear on the battery.

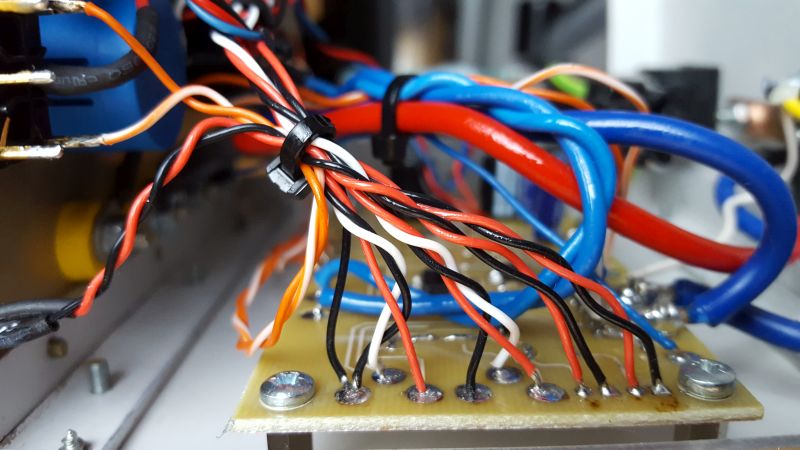

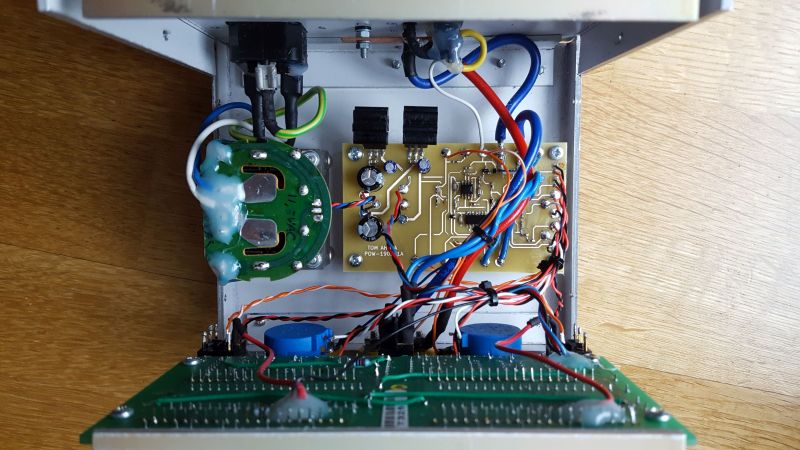

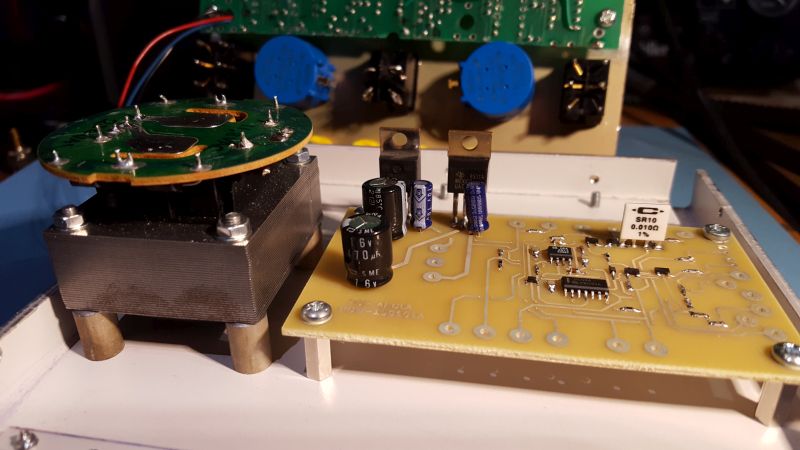

The LCD Voltage and Current meter displays are based on the TC7106 chip. I had in my treasure bin a recycled meter board that I reused. The current sink is based on the classical 2N3055, which I had in the bin too. To boost the current gain I connected a TIP31C in a darlington configuration. Current measurement is through a 0.01 ohm 4-wire resistor, giving 100mV voltage drop at 10A current. A TLC072 dual Op-Amp is used as the current control loop amplifier and cut-off voltage comparator. It has a good output drive capability to drive the base current of the current sink darlington pair. The power supply transformer is also a recycled item from my treasure bin.